Automatic Inspection Method for LCD Panel

Introduction

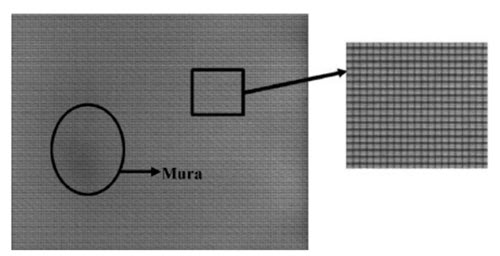

Liquid crystal displal (LCD) panel, whose significance needs no mentions in both daily and scientific activities, meets its manufacturing bottleneck in the process of Mura defects inspection. Tranditional detection techniques employ spatial oversampling in principle and frequency-domain filtering in parsing, but when compared with manual tests they are still not adequate enough on robustness and reliability, notwithstanding the exceeded cost and complexity. By adopting computational imaging methods, this group modified the characterization model, proposed a highly precise inspection technique, built a test platform with great efficiency and finally put it into practice successfully. The project along with its accompanying theories has great industrial potential in fields relating to visual inspection and regional extraction.

Highlights

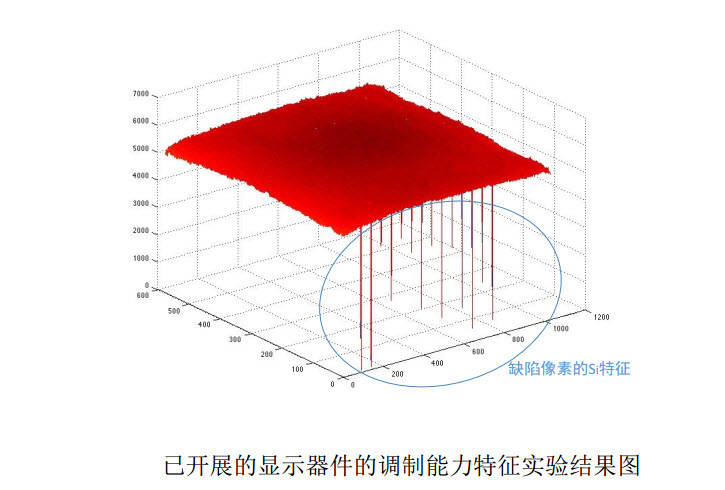

A Theoretical Modelization: To Characterize the Modulation Ability of Panel Display Devices

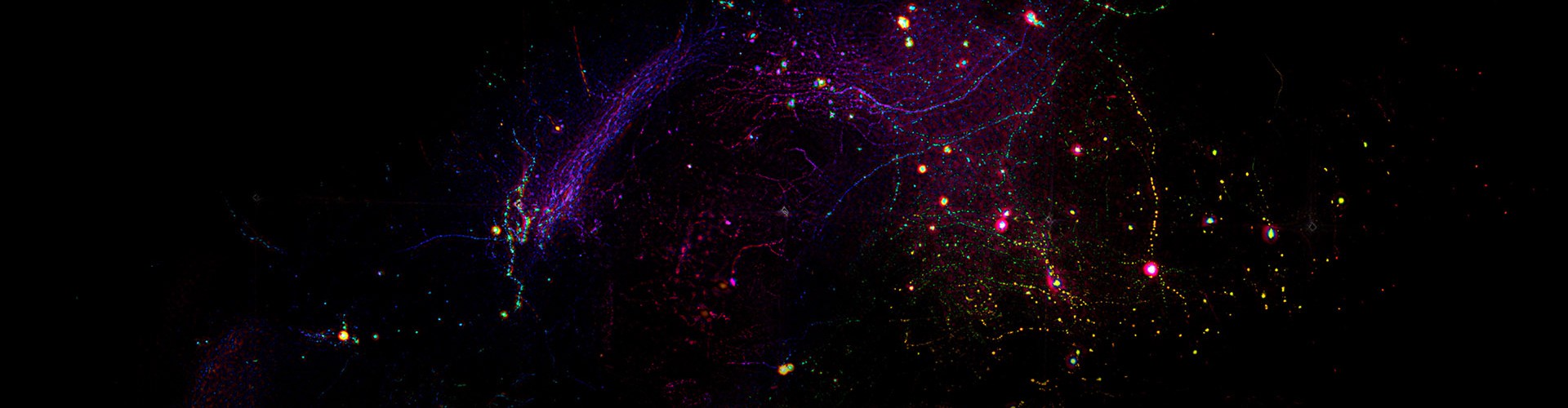

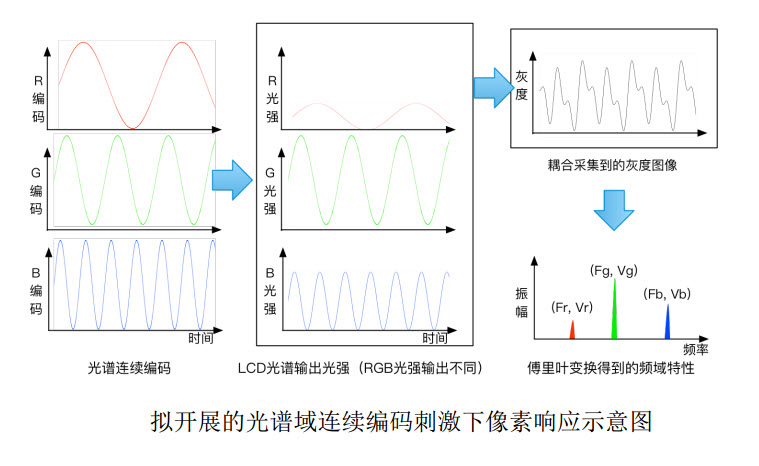

An Inspection Techonology: To Detect the Flaws Effectively and Effeciently

Non-edge characteristics extraction method for flawed region

Classification of display defects

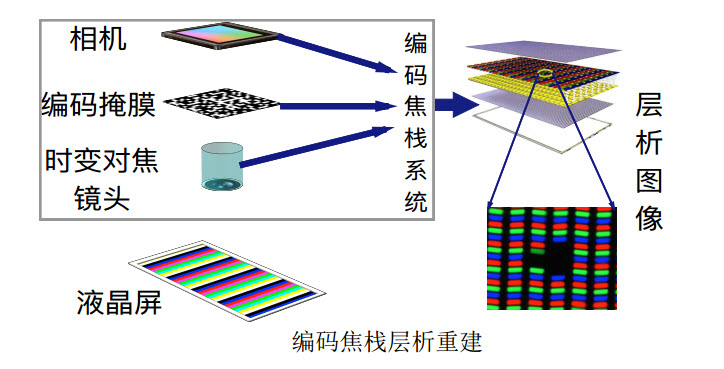

Depth differentiation of display defects

Research Production

The inspection technique has been introduced as a whole by the LCD production line of Samsung, and was awarded the Second Class Prize for Guangdong Science and Technology Progress Award in 2015. Related spectral coupling code acquisition method and computation reconstruction fast sensing technique, when being introduced to print-related fields, was awarded the First Class Prize for China Electronics Society Technology Progress Award in 2015.